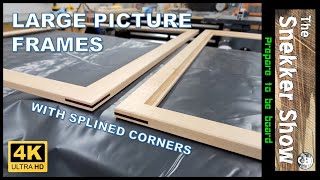

How to make large picture frames with splined corners

How to make large picture frames with splined corners

These frames are built with hard maple, and feature purpleheart splines in the corner for strength and style. Picture frames aren’t very difficult to make, but there are a lot of small details that can change the outcome. I’ve made plenty of picture frames throughout the years, and it always seems to take longer than it should because of the time required to calibrate power tools, build or set up jigs, and verify that each angle and measurement is exactly as it should be. This was one of my smoothest builds yet, mostly thanks to some extra time spent making a better spline jig for the table saw.

These frames are built with hard maple, and feature purpleheart splines in the corner for strength and style. Picture frames aren’t very difficult to make, but there are a lot of small details that can change the outcome. I’ve made plenty of picture frames throughout the years, and it always seems to take longer than it should because of the time required to calibrate power tools, build or set up jigs, and verify that each angle and measurement is exactly as it should be. This was one of my smoothest builds yet, mostly thanks to some extra time spent making a better spline jig for the table saw.

I decided that I no longer like metal turn buttons, so I’ve been 3D printing my own. You can find them on my Etsy shop while supplies last:

https://thesnekkershow.etsy.com/listing/1554696822

You can also find me on:

Instagram: https://www.instagram.com/thesnekkershow/

Etsy: https://thesnekkershow.etsy.com (woodworking stuff)

Etsy: https://generalvarietyvault.etsy.com (non-woodworking stuff)

Ko-fi: https://ko-fi.com/thesnekkershow

Printables: https://www.printables.com/@SnekkerShow_887377

And even here: https://www.youtube.com/@relaxing-naptime-music

Tools and supplies:

Whiteside 3/4″ 1084 straight bit: https://amzn.to/3wQTNKQ

Whiteside ultimate pattern bit: https://amzn.to/3oNdFKZ

Freud Chamfer Bit: https://amzn.to/35y2VYO

DeWalt 1-3/4 HP router kit: https://amzn.to/3iXgUzD

Self-Centering Drill Bit: https://amzn.to/3wGqr1J

2′ Universal T-Track: https://amzn.to/3gApZwz

4′ Universal T-Track: https://amzn.to/2SBpZmX

Quick Release Band Clamp: https://amzn.to/3vIuAAV

Turn Buttons: https://thesnekkershow.etsy.com/listing/1554696822

Keyhole hangers: https://amzn.to/3q6fQL8

Satin water-based polyurethane: https://amzn.to/3iT46tJ

Fuji Mini-Mite 4 PLATINUM: https://amzn.to/3gIYlxD

Fuji Q4 PLATINUM: https://amzn.to/3wHmbiB

Chapters:

0:00 Design

0:50 Wood preparation

3:28 Cutting miters on the table saw

5:20 Rabbets and edge details

8:02 Clamping and gluing

11:35 Corner splines

18:17 Keyhole hangers and turn buttons

21:44 Sanding and finishing

24:46 Final details

This video is not sponsored. I paid for everything and used my own time. As an Amazon Associate, I may earn a small commission if you use these links to make a purchase.

you’re not going to cut your fingers off on the table saw. don’t think like that.

if the blade is sharp, the fence is locked in, use a push stick, keep the material against the fence, and some downwards pressure at all times, you will be fine.

respect the machine and keep your fingers away from the blade, especially over the blade, and you will be fine.

never rush the cut using the table saw, because that’s when the material is pushed up and toward you.

you can easily over power the motor on a 110V motor on a table saw, but staying safe, and respecting the machine is rule number one. fear works against you when there’s not need for it. yours using other tools to avoid the table saw, and that speaks volumes. understanding the operation of each tool is key.

if you use each tool as it was intended, you’ll be fine. cutting thin tiny strips of wood on the table saw can be done safely if you use proper techniques, and you’ll never get cut. never. pay attention 100% of the time, and take your time.

it’s the most useful tool in the shop.

i’ve been using a table saw for 35 years, and still respect it like it’s the devil.

i pay attention to what i’m doing snd make sure how i’m cutting won’t hurt me.

EVERY TIME.

when you notice the blade getting dull because it takes more pressure to cut, it it starts to burn, swap it out for a fresh blade. i just would not avoid the table saw. you can do so much with it and be safe about it.

cheers !

no, not cheers, don’t have a drink lol

cheers as in ciao, or good bye

Love the Hank Hill voice!

Loved this video and just subscribed; love your sense of humor, precision, and educational style. Thanks so much; have to make two 4’ x8’ frames so this really helped me think through the process.

Usually these videos show how to do it when you have the perfect materials to work with.

You also show how to get the perfect materials, love it. 👌

I’ve watched numerous frame jig videos and it’s amazing the number of people that can’t pronounce the word "picture" they all say pitcher.

This was such overkill.

😂😂fooled me with the reverse clip, didn’t even notice

Please lower that blade and don’t reach over the blade, take that ring off as well other than that great video

Sketchup is free cad software and once you watch a few videos, becomes pretty easy to use

Narrated by Nixk Offerman

Beautiful frames!

so much to learn from this. and the hilarious deadpan! such a pleasure to watch.

The dust collection on your Router Table is dialed in!

So you had double use of the diapers…

Excellent job! DD

Lots and lots of good tips! Thanks.

Excellent work. Do you thin the polyurethane when you spray it?

Excellent work and an enjoyable video to watch.

Love a video on that spline jig!

Love the visio visual. It’s really to helpful to understand what is going to happen.

I like your dry sense of humor and dad jokes.

Cool beans man!

Great video and narration. Love the jokes. You have the whole range: Band Clamp; Charlie Browns Shirt; Diapers. When routing the mortises, you could have used a longer template board. If the template “hooked” over the top of the picture frame, you could be assured the mortises were exactly 12” below the top. Noticed that you had a stop pice to assure the mortises were centered side-to-side.

excellent job and really great quips!

📲💻📲📲

Very well done, sir. Beautiful work! And your video was great, your commentary was hilarious 😎

i learned several tips. Thank you and well done.

I hadn’t run across this video before but found it timely, regardless. I too cut large frames , especially now that I have a wide format printer. My new jig resembles a number of others on YT, except that it can accommodate lengths up to about 47”, and the stop is cut at a 45 degree angle so I can precisely cut to a 1/16” in length.

Your process I think is spot on. I love your spline cutting jig and I think I’m going to borrow its design. I especially like the clamping configuration. Currently I’m using a jig exactly like your old one, and have been searching for another solution.

Your final product was exquisite. The miters looked perfect. I only hope the posters that went into the frames were worthy!

You can skip the step of changing the jig setup by simply reversing it, assuming the miter slots in the saw table are symmetric to the blade. This will also ensure that the spline is centered.